02.02.17

Specialty geosynthetics are forming a cornerstone of the evolving trend for more environmentally sustainable infrastructure and construction.

Exclusive data in the new Smithers Apex report—the Future of Specialty Geosynthetics to 2021—tracks how this market will grow steadily across the next five years driven by greater acceptance of such terrain stabilizing materials, especially in key developing markets such as China and India.

Global consumption of these plastic products—geotextile, geomembranes, geogrids, geosynthetic clay liners, geowalls and geocomposites—exceeded eight million tons in 2016 for the first time. This figure will climb above nine million tons in 2021. A market Smithers valued at $16 billion in 2013, is now worth well over $18 billion. This expansion will continue at a year-on-year rate of 2.7% across the next five years to reach $21 billion in 2021, a 15% real terms increase.

The advance of specialty geosynthetics can be seen to rest on dual foundations:

Expanding demand for geosynthetics is posited on their superior performance compared to accepted, naturally occurring soil stabilizing materials—like cotton, straw or coconut fiber (coir). Using bespoke solutions made from plastics – such as polyurethane (PUR), polypropylene (PP) and various grades of polyethylene – give more durable solutions. This translates into reduced maintenance cycles for site operators and greater safety, by for example better retaining toxic materials, like heavy metals from coal ash deposits.

Smithers’ comprehensive analysis tracks how a growing body of regulatory requirements directed toward sustainable infrastructure investment, is supporting wider use of these specialist materials.

The cost of any specialty manufactured geosynthetic is directly linked to that of its hydrocarbon feedstocks, which are its basic raw material. As these are forecasted to remain fairly constant—or even see slight decline through to the end of decade. Thus from a supply side perspective the market is favorable with fewer bottlenecks expected.

Product Types

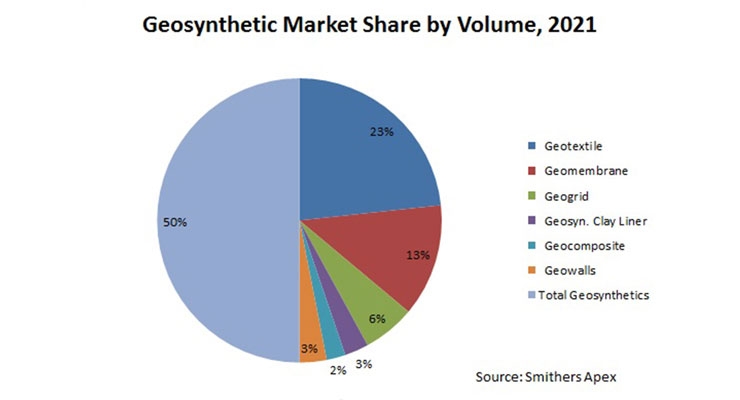

Demand for geosynthetic materials is linked to the applications in which they are used. In 2016, geotextiles represented 47% of world consumption, which is 3.8 billion meters, and 37% of global value. Nearly 87% of these are used in road building or similar transportation applications.

Geomembranes account for over 24% of the 2016 world market by value, but slightly less by volume. Its principal use (58%) is in roofing for buildings.

Waterways, like canals, meanwhile account for the majority of consumption of geocomposites (65%) and geosynthetic clay liners (72%).

Geomembranes for all applications will slightly increase marketshare across 2016-2021, with geotextiles and geowalls declining slightly. Geogrid, geocomposites and clay liners will maintain their relative marketshares against a backdrop of steady expansion for the wider market.

This is because market segments for specialty geosynthetics all now have a significant base upon which to build, even as superior products, new regulations and wider usage push total demand.

End-use Applications

Smithers divides the end-uses for specialty geosynthetics into four key applications:

Geographic Demand

Use of specialty geosynthetics today is most common in Western Europe and North America. These represent 32% and 17% respectively of the eight billion square meters used worldwide in 2016. Asia-Pacific is the second largest regional market with a 30% marketshare in 2016. Asia’s transition economies the fastest growth prospects for 2016-2021, giving a 3.4% CAGR region wide across this period.

China is the key national market in Asia and already accounts for more than 60% of specialty geosynthetics consumption. Demand is forecast to remain high, due to initiatives like the 13th Five-Year Plan, which promises to build:

Both India and China will see a rapid increase in use for liquid containment in MSWs – addressing a long neglected environmental hazard. Their relative growth rates in this application for the five years to 2021 are 12% and 8%, respectively.

Technical Developments

Technical R&D and product evolution in the next five years are likely to focus on five key areas:

Metallocene Polypropylene

The use of metallocene catalysts used in the production of PP nonwovens is advancing and producing a new generation lighter weight geotextiles. This allows new geosynthetic grades – like Total’s Lumicene MR2001 and MR2002 launched in 2015 – that can deliver the same performance as heavier conventional PP products. Furthermore they are inert once buried and will not alter the chemical balance of the soil into which they are placed.

For manufacturers there are advantages too in processing metallocene catalyzed PP geosynthetics. These include:

Graphene

Graphene has been hailed as a pivot for a future materials revolution in a wider range of industries—though scaling production of a material first produced with adhesive tape and pencil graphite has been a major barrier.

In April 2016, a small, research-oriented company based in Australia, Imagine Intelligent Materials (IIM), announced the commercial application of graphene coating on geotextiles. It is working with Geofabrics Australasia—Australia’s largest geotextile company—to develop a ‘game-changing’ graphene-coated geotextile with advanced leak-detection capabilities. IIM also notes that the improved structural properties of graphene would add considerable strength, with little additional weight, which will help future geosynthetic products meet more robust strength requirements in regulations.

The geosynthetics segment is thus likely to devote more money to evolving graphene technology, though the principal hurdle remains achieving volume production at a reasonable price.

Nanofibers

A more immediate and allied trend for the geosynthetics industry is the evolution of nanofiber nonwovens. Due to their inherently low density and large surface area to mass, nanofiber structure can deliver a nonwoven fabric that is extremely light, adding little weight to applications involving geocomposite structures. These simultaneously promise superior filtration properties – to both liquid and gases.

As with graphene the challenge is to transition laboratory grade nanofiber manufacturing to commercial scale. Current platforms rely on conventional, coaxial, melt or emulsion electrospinning technology; though one new approach needleless electrospinning – first described in an academic paper in 2012 – holds more promise for volume manufacturing.

Thus, there is every reason to expect commercial-scale nanofiber production during the next five to 10 years, with geosynthetics one of the nonwoven segments where this will lead to new and more valuable products.

Leak Detection

Two other nanomaterials—nanoparticulate carbon black and carbon nanotubes—are being developed for geosynthetic applications. This proposition relies on their electrical conductivity to enable enhanced geosynthetics that could detect leakages in landfills and coal ash containment structures—a significant environmental issue.

Current flowing through—for example, a polypropylene nanotube enhanced sheet—would alter areas of a geosynthetic subject to additional mechanical stress. This would give an early warning of those areas that are prone to breaking and leakage in liquid containment structures. This in situ real time monitoring would allow remedial action to be taken more quickly and effectively.

As graphene is also highly conductive it too could carry out this function once supply issues are resolved.

Production Improvements

Current processes for producing geosynthetic rely on needlepunch manufacturing processes. Though familiar, these have the drawback that they place stress on the fibers as they are manufactured, which diminishes tensile strength (tenacity) during use. New technologies that enable better tenacity via a higher draw ratio, would decrease elongation are under investigation.

A similar focus is taking place in geomembranes, with research and development at companies such as U.S.-based Raven Industries, which aims to make larger multi-layer blown films. These would offer faster production, stronger films, and hence greater flexibility in application.

The Future of Speciality Geosynthetics to 2021 [http://www.smithersapex.com/market-reports/the-future-of-specialty-geosynthetics-to-2021] presents volume and value forecasts by end-use sector and geographic region for this dynamic segment. Following several stages of primary and secondary research, it examines key drivers and trends, which include economic, social and demographic, trends within decorative and the different industrial coatings segments and key new technologies for future innovative high-performance coatings.

Exclusive data in the new Smithers Apex report—the Future of Specialty Geosynthetics to 2021—tracks how this market will grow steadily across the next five years driven by greater acceptance of such terrain stabilizing materials, especially in key developing markets such as China and India.

Global consumption of these plastic products—geotextile, geomembranes, geogrids, geosynthetic clay liners, geowalls and geocomposites—exceeded eight million tons in 2016 for the first time. This figure will climb above nine million tons in 2021. A market Smithers valued at $16 billion in 2013, is now worth well over $18 billion. This expansion will continue at a year-on-year rate of 2.7% across the next five years to reach $21 billion in 2021, a 15% real terms increase.

The advance of specialty geosynthetics can be seen to rest on dual foundations:

- Expansion of infrastructure building projects.

- Technical advancement, offering the prospect of new better performing geosynthetics.

Expanding demand for geosynthetics is posited on their superior performance compared to accepted, naturally occurring soil stabilizing materials—like cotton, straw or coconut fiber (coir). Using bespoke solutions made from plastics – such as polyurethane (PUR), polypropylene (PP) and various grades of polyethylene – give more durable solutions. This translates into reduced maintenance cycles for site operators and greater safety, by for example better retaining toxic materials, like heavy metals from coal ash deposits.

Smithers’ comprehensive analysis tracks how a growing body of regulatory requirements directed toward sustainable infrastructure investment, is supporting wider use of these specialist materials.

The cost of any specialty manufactured geosynthetic is directly linked to that of its hydrocarbon feedstocks, which are its basic raw material. As these are forecasted to remain fairly constant—or even see slight decline through to the end of decade. Thus from a supply side perspective the market is favorable with fewer bottlenecks expected.

Product Types

Demand for geosynthetic materials is linked to the applications in which they are used. In 2016, geotextiles represented 47% of world consumption, which is 3.8 billion meters, and 37% of global value. Nearly 87% of these are used in road building or similar transportation applications.

Geomembranes account for over 24% of the 2016 world market by value, but slightly less by volume. Its principal use (58%) is in roofing for buildings.

Waterways, like canals, meanwhile account for the majority of consumption of geocomposites (65%) and geosynthetic clay liners (72%).

Geomembranes for all applications will slightly increase marketshare across 2016-2021, with geotextiles and geowalls declining slightly. Geogrid, geocomposites and clay liners will maintain their relative marketshares against a backdrop of steady expansion for the wider market.

This is because market segments for specialty geosynthetics all now have a significant base upon which to build, even as superior products, new regulations and wider usage push total demand.

End-use Applications

Smithers divides the end-uses for specialty geosynthetics into four key applications:

- Transportation – roads and highways, tunnels, and bridges

- Industrial – Municipal solid waste (MSW) landfills and construction debris and demolition (CCD)

- Liquid retention – Coal ash containment ponds and waterways

- Construction – Principally roofing and building substructures

Geographic Demand

Use of specialty geosynthetics today is most common in Western Europe and North America. These represent 32% and 17% respectively of the eight billion square meters used worldwide in 2016. Asia-Pacific is the second largest regional market with a 30% marketshare in 2016. Asia’s transition economies the fastest growth prospects for 2016-2021, giving a 3.4% CAGR region wide across this period.

China is the key national market in Asia and already accounts for more than 60% of specialty geosynthetics consumption. Demand is forecast to remain high, due to initiatives like the 13th Five-Year Plan, which promises to build:

- 10,000km of inter-city rail connections

- 3000km of urban rail lines

- 30,000km of expressways

- 20,000km of rural roads

- 50 more civilian airports

Both India and China will see a rapid increase in use for liquid containment in MSWs – addressing a long neglected environmental hazard. Their relative growth rates in this application for the five years to 2021 are 12% and 8%, respectively.

Technical Developments

Technical R&D and product evolution in the next five years are likely to focus on five key areas:

Metallocene Polypropylene

The use of metallocene catalysts used in the production of PP nonwovens is advancing and producing a new generation lighter weight geotextiles. This allows new geosynthetic grades – like Total’s Lumicene MR2001 and MR2002 launched in 2015 – that can deliver the same performance as heavier conventional PP products. Furthermore they are inert once buried and will not alter the chemical balance of the soil into which they are placed.

For manufacturers there are advantages too in processing metallocene catalyzed PP geosynthetics. These include:

- Increased production throughput

- The elimination of the need for peroxides to obtain narrow molecular weight distribution and high melt flow indices

- Less extractables and fumes generated in the factory

Graphene

Graphene has been hailed as a pivot for a future materials revolution in a wider range of industries—though scaling production of a material first produced with adhesive tape and pencil graphite has been a major barrier.

In April 2016, a small, research-oriented company based in Australia, Imagine Intelligent Materials (IIM), announced the commercial application of graphene coating on geotextiles. It is working with Geofabrics Australasia—Australia’s largest geotextile company—to develop a ‘game-changing’ graphene-coated geotextile with advanced leak-detection capabilities. IIM also notes that the improved structural properties of graphene would add considerable strength, with little additional weight, which will help future geosynthetic products meet more robust strength requirements in regulations.

The geosynthetics segment is thus likely to devote more money to evolving graphene technology, though the principal hurdle remains achieving volume production at a reasonable price.

Nanofibers

A more immediate and allied trend for the geosynthetics industry is the evolution of nanofiber nonwovens. Due to their inherently low density and large surface area to mass, nanofiber structure can deliver a nonwoven fabric that is extremely light, adding little weight to applications involving geocomposite structures. These simultaneously promise superior filtration properties – to both liquid and gases.

As with graphene the challenge is to transition laboratory grade nanofiber manufacturing to commercial scale. Current platforms rely on conventional, coaxial, melt or emulsion electrospinning technology; though one new approach needleless electrospinning – first described in an academic paper in 2012 – holds more promise for volume manufacturing.

Thus, there is every reason to expect commercial-scale nanofiber production during the next five to 10 years, with geosynthetics one of the nonwoven segments where this will lead to new and more valuable products.

Leak Detection

Two other nanomaterials—nanoparticulate carbon black and carbon nanotubes—are being developed for geosynthetic applications. This proposition relies on their electrical conductivity to enable enhanced geosynthetics that could detect leakages in landfills and coal ash containment structures—a significant environmental issue.

Current flowing through—for example, a polypropylene nanotube enhanced sheet—would alter areas of a geosynthetic subject to additional mechanical stress. This would give an early warning of those areas that are prone to breaking and leakage in liquid containment structures. This in situ real time monitoring would allow remedial action to be taken more quickly and effectively.

As graphene is also highly conductive it too could carry out this function once supply issues are resolved.

Production Improvements

Current processes for producing geosynthetic rely on needlepunch manufacturing processes. Though familiar, these have the drawback that they place stress on the fibers as they are manufactured, which diminishes tensile strength (tenacity) during use. New technologies that enable better tenacity via a higher draw ratio, would decrease elongation are under investigation.

A similar focus is taking place in geomembranes, with research and development at companies such as U.S.-based Raven Industries, which aims to make larger multi-layer blown films. These would offer faster production, stronger films, and hence greater flexibility in application.

The Future of Speciality Geosynthetics to 2021 [http://www.smithersapex.com/market-reports/the-future-of-specialty-geosynthetics-to-2021] presents volume and value forecasts by end-use sector and geographic region for this dynamic segment. Following several stages of primary and secondary research, it examines key drivers and trends, which include economic, social and demographic, trends within decorative and the different industrial coatings segments and key new technologies for future innovative high-performance coatings.