Tara Olivo, Associate Editor10.10.16

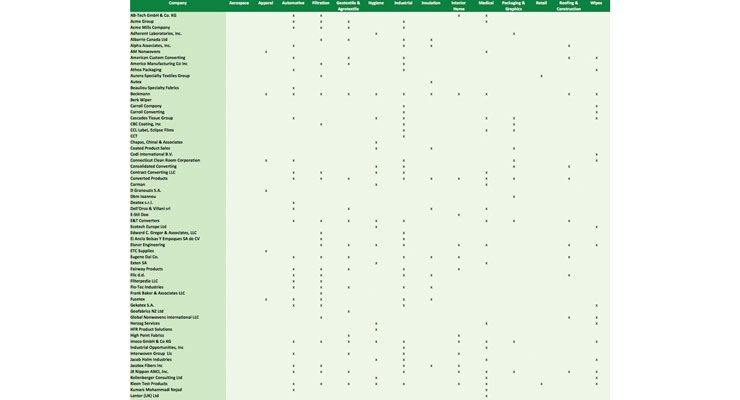

Converting companies are an integral part of the nonwovens supply chain. For all of the advantages the industry’s products provide, a lot has to happen prior to their end use. Nonwovens need to be cut into a variety of shapes and sizes, scaled down to become a single-use product, as well as printed, packaged and more. Sometimes the process is simple, and sometimes more complex, with converting companies using the latest technology to add value to products and make them easier to use. The following is a compilation of capabilities and services of some the nonwovens industry’s leading converters.

Athea Laboratories

Athea Laboratories has been in business for over 50 years and is the leader in specialty wipes, liquid, and powder contract manufacturing and packaging. Its expertise and experience gives customers an extensive variety of product formats to serve numerous end-user markets with their private labeled product. As an EPA and FDA facility, Athea’s manufacturing capabilities include custom wipe converting, custom formula development, blending services, onsite chemists, formula-substrate compatibility testing, graphics and technical and regulatory support. Athea can offer its customers a turnkey solution to their packaging needs at low minimums.

www.athea.com

Aurora Specialty Textiles Group

For over 130 years, Aurora Specialty Textiles Group, Inc. (Aurora) has been a leading, world-class finisher of both woven and nonwoven fabrics. Utilizing state-of-the-art equipment and technologies, Aurora specializes in coating and finishing products for print media, home furnishings, and industrial belting, pressure sensitive tapes and medical and industrial products.

Recently, Aurora has opened a new state-of-the-art manufacturing operation in Yorkville, IL, which offers ultra wide width (134-inch) coating and finishing techniques. This enhanced capability secures its place in today’s changing global textile market as an innovative global provider of textile solutions. This move expands Aurora’s ability to provide product solutions for a wide range of applications and further strengthened its ability to be responsive, efficient and price competitive.

Aurora is a Meridian Industries Inc. company, which is a privately held, family-owned company headquartered in Milwaukee, WI.

www.auroratextile.com

Beckmann Converting

Beckmann Converting continues to upgrade its high tech, ultrasonic laminating equipment, both in bonding capability and in web handling, to create wide web, multilayer and multifunction composites. Upgrades have allowed the company to process more efficiently and to process more types of raw materials. Beckmann operates as a contract or toll laminator and is able to create, from two-layer composites to six-layer composites. It can create them as wide as 120 inches and slit in line, to any width a customer or its next step converter requires. These composites can be combinations of nonwovens, films, knits, wovens or meshes.

Ultrasonic laminating has a unique place in the creation of multi-layer composites because nothing other than the original materials are used in that process. This makes it a true “green” process. As long as there is sufficient thermoplastic content in the layers to be laminated, the ultrasonic energy melts the materials at the bonding points, making it the bonding link of the individual layers, unlike adhesive bonding, which introduces foreign substances into the composites. Because ultrasonic lamination is a “point bonding process,” all of the properties of the raw material layers, in between the bond points, are the same as before lamination, which include properties such as strength, loft, breathability, filtration and chemical resistance. Beckmann has successfully produced multi-layer composites for applications such as filtration, environmental, protective apparel, protective covers, healthcare products, cleanroom wipes and many more.

www.beckmannconverting.com

Elsner Engineering

Elsner Engineering has been producing converting machinery for various paper, film, foil and nonwovens end-uses for decades. Its experience coupled with its passion to bring innovative, purpose-built machinery to life means Elsner is a great resource when it comes to strategizing on best ways to boost productivity, especially as related to integrating automation into a business’s production lines. Elsner’s consultative approach can help businesses determine the value of automation based on their unique manufacturing circumstances. Elsner’s goal is to help its customers get on-track to Turn the Key and GO.

www.elsnereng.com

Kleen Test Products Corporation

Kleen Test Products is a privately held, family-owned company headquartered in Port Washington, WI, that’s been in business for over 70 years. Kleen Test’s product and service offerings include contract manufacturing and product development services in a number of product segments such as wet wipe and dryer sheet manufacturing, die cutting nonwovens, coating and conversion of specialized nonwoven products, liquid filling and bulk blending.

Recently, Kleen Test Products launched SNAP PAD, a patented, all-in-one single-use applicator that allows the user to saturate the nonwoven at the time of use. By gently squeezing the outer casing of the applicator, a burst of solution is released onto the nonwoven pad. The volume of solution and the diameter of the pad applicator can be customized to meet a product’s specifications. SNAP PAD can be used for a number of applications including first aid, beauty care, personal care, home care, automotive and more.

www.kleentest.com

Majilite Corporation

Majilite Corporation, a Meridian’s Industries Company, located in Dracut, MA, is a custom manufacturer of films and film laminates. Most any liquid polymer, solvent or water based, can be used to produce films in the 0.5 to 10.0 dry mil range. Majilite can then laminate these films, to most any fabric, woven or nonwoven, or further process them to create single or multi-layer composites. The company has the following coating capabilities: cast or transfer films, direct coating, reverse roll coating, saturation, printing, and knife over roll coating. Majilite also has the capability to post laminate, emboss, buff or sand, quilt, and rotogravure printing. Its plant is state-of-the-art not only in its capabilities but also in how it can virtually eliminate solvent emissions from its processes. R&D and product development labs are located at Majilite’s plant site along with a Quality Control laboratory.

www.majilite.com

Micrex

Micrex Corporation is the developer and manufacturer of the Micrex/Microcreper family of compressive treatment machinery for nonwovens, paper, films, composites, and textiles. Companies worldwide use Micrex technology to add softness, bulk, drape, absorbency, extensibility, and stretch to a wide range of products.

Micrex expands upon its capabilities by providing product development through the Micrex Innovation Lab. This integrates with contract Microcreping services for those firms whose current needs do not yet require the purchase of a dedicated Micrex/Microcreper system. Micrex is prepared to support projects from initial development through large scale production. All nine configurations of Micrex/Microcreper are available for contract production.

In 2016 no-cost lab scale screening trials are available to qualified customers. For information about this program, visit: http://micrex.com/screening-trials/.

www.micrex.com

National Wiper Alliance

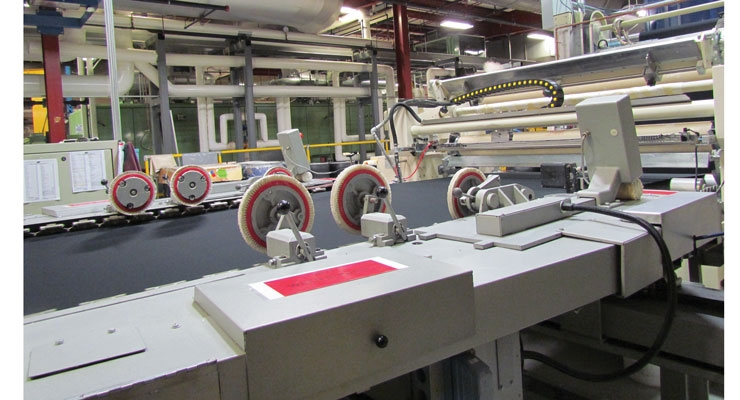

National Wiper Alliance (NWA) is the largest operation in the U.S. focused on nonwoven dry wipes converting and private labeling. Operating out of its 500,000 square foot state-of-the-art facility located just outside Asheville, NC, NWA has over 30 converting lines offering slitting, inner folding, folding, sheeting, and perforating—both with core and coreless, as well as printing—with both inline and dedicated print lines. Additional in-house services offered include product development, sample runs, product testing, warehousing, customer inventory management, distribution and logistical support. Products converted by NWA can be found in the retail, aerospace, automotive, industrial, food service, hospitality, medical, government, military and janitorial markets.

Earlier this year, NWA purchased a 42-acre site with a 152,000 square foot warehouse located near its current facility. Jeff Slosman, president of NWA, says, “With the growth we have experienced over the past few years, ensuring we would have enough space to maintain our efficiencies was a concern. The new location will guarantee we have space to continue to offer our customers the service they have come to expect when working with NWA while offering us the land for expansion in order to handle our continued growth for the years to come.”

Proudly registered to ISO 9001:2008 standards, National Wiper Alliance and its owner Jeff Slosman have received numerous awards over the past year. These awards include: SBA-North Carolina 2015 Small Business Person of the Year – Jeff Slosman; NC Chamber of Commerce – 2015 Manufacturer of the Year – Honorable Mention; Business NC Magazine – 2015 NC Small Business of the Year and Wake Forest Family Business Center – 2016 NC Family Business of the Year.

www.nationalwiper.com

Nonwovens of America

Nonwovens of America, Inc. (NOA) is located in Swannanoa, NC, operating a 5.4-meter air-lay needlepunch line and running colors in a weight range of 3.5 ounces per square yard to 34 ounces per square yard. In addition to the needlepunch line, NOA provides custom converting services which include a 10-color, 99” wide rotary screen print line, blanket lines, an inline calendar, and slitting and re-rolling. NOA offers toll converting services on the needlepunch line as well as all other converting services. The main areas of focus are automotive, retail, geotextile, industrial and emergency blankets. NOA provides in-house customer service, product development, warehousing, logistics and distribution support.

www.nonwovensofamerica.com

Rockline Industries

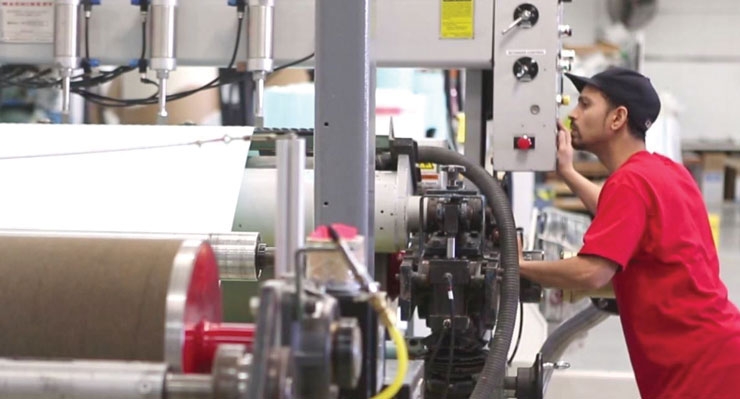

Rockline Industries is a family-owned and run business since its founding in 1976. The company has grown from a 35-person company to a 2000-person organization designing, making and shipping products all over the world. Rockline is committed to safety, quality, integrity, sustainability, and excellence in everything it does. Rockline Contract Manufacturing Services (CMS) are built on the core values of integrity, dignity, respect, and hard work.

The expertise Rockline CMS continues to demonstrate, guides customers into new product solutions and leads continuous improvement in innovations with materials, manufacturing platforms and technologies. CMS offers a fully diversified portfolio of converting and packaging equipment in an environment that is designed to be a world class leader in quality, while intentionally practicing strategies that minimize its global footprint.

Values: Rockline says its values define them. They reinforce to all of their stakeholders—customers, associates, suppliers and communities—just how much Rockline appreciates them. They allow Rockline to build a value-based business and reputation within the industry at large. Within the contract manufacturing sector, its values ensure that Rockline maintains a global recognition as the premier supplier in the industry, producing innovative solutions, ensuring mutually profitable partnerships and providing customers with important and trusted services that create lasting relationships.

The word “urgency” describes the sense with which Rockline seeks to earn recognition by its customers as the unmatched leader in contract manufacturing. This urgency involves five basic imperatives — Renew (invest all earnings in continuous improvement), Respect (treat others as we want to be treated); Integrity (do the right thing); Teamwork (individual goals are secondary to team goals); and Excellence (best in class). Rockline fosters a culture of integrity, service and personal growth. The company delivers excellence in its products, process and services.

Integrity: Rockline does not compromise integrity for financial gain. Its partnerships are managed with the utmost respect while striving for manufacturing flexibility and to provide the best net value to our customers.

Every Rockline associate is asked, “Do what you think is right – every day.” These simple words can make for tough choices, but Rockline says it will never stop trying to do the right thing. For example, the company has a reputation in the wipes industry of uncompromising integrity with respect to maintaining strict confidentiality to protect and preserve intellectual property for the ongoing business security of its customers.

Continuous Improvement: Rockline embraces continuous improvement through product innovation, capital reinvestment and through dedicated passionate leadership and cross functional teams. Its values are applied to all stakeholder relationships—from customers, associates, and suppliers on out to the communities at large whose needs it meets with uncompromising effort. It works every day to confirm just how much Rockline values each and every one of them. Rockline understands this is the only way to build and sustain the reputation it seeks within the industry. In the words of its CEO Randy Rudolph, “We won’t make a product we wouldn’t buy for ourselves. We aim for the sweet spot. Rockline is big enough to give our customers the resources and vision of a global company, yet we are small enough to value each and every customer.”

Innovation: At Rockline, its core strength is the quality and innovation of its product. The focus of its contract manufacturing group is to deliver excellence in customer service by supporting its customers with custom manufacturing and cutting-edge product and packaging while strengthening its speed to market. This is supported by a winning combination of technical leadership along with the most diverse manufacturing platforms in the industry. It listens, innovates and collaborates with its customers to deliver customer specific solutions that leverage its expertise in material, manufacturing and innovation.

Sustainability: It is Rockline’s commitment and passion to put its own reputation on the line every day, to measure and report its own progress so customers don’t have to. That’s what sustainability means to them. For information about Rockline’s environmental program success of the past six years and its 2020 environmental targets download the Sustainability Report: http://www.rocklineind.com/environmental-sustainability/. Among the key accomplishments highlighted in the report is a 21% intensity reduction in energy compared to 2009 levels. Over the last six years, the company has focused on energy efficiency and invested in lighting upgrades, motion sensor installations, roof insulation projects, smart compression systems, the adoption of battery-electric forklifts, and the installation of a geothermal heating and cooling system. Energy reduction also provides the benefit of reducing the company’s carbon footprint and helped the company to achieve a 22% intensity reduction in greenhouse gas emissions.

Rockline continues to aggressively move from fossil fuels toward clean, low carbon energy, designing waste and inefficiency out of its system, and embracing strategies like reuse, recycling, and energy recapture to reduce landfill use and waste water production. Rockline strives for Ecological Intelligence in its end products, using less material where it can, and sourcing natural and recycled materials wherever possible.

www.rocklineind.com

Superior Felt & Filtration

Superior Felt & Filtration is a quality and customer service driven manufacturer, distributor and converter of nonwoven felt and filtration media. Superior offers a wide range of nonwoven products to meet the immediate needs of multiple technical markets. Superior serves numerous markets including medical, automotive, aerospace, appliance, industrial, decorative and more. Already stocking the largest inventory of micron, CFM, synthetic, high temperature, FDA grade and SAE wool felts in North America; Superior is also the North American distributor and converter of Technostat, a sub-micron, high-efficiency filter media: The versatility of Technostat allows Superior to exceed expectations in Viral/Bacterial, CPAP, NIOSH, Respirator, HEPA and breathable packaging and wound care markets. SFF also provides white room fabrication which further supports its position in lamination, ultrasonics, slitting, heat sealing, die-cutting, printing, private label packaging and other value added services. From container loads of roll good media to life saving medical filtration technology, Superior can take an idea from concept to completion.

www.superiorfelt.com

Web Industries

Web Industries continues to focus on improving capabilities and increasing capacity to better serve the health and hygiene markets. In 2016, the company made significant investments to upgrade several spooling assets at the company’s Fort Wayne, IN, facility. Home to several of the largest custom-designed spooling lines in the work, Web Fort Wayne processes nonwovens, films, and other materials, and provides contract converting, spooling, printing, and supply chain management services in a single location.

Capable of accepting 120" wide master rolls, Web has invested in upgrading its “large format spooler” to utilize the latest industrial control interfaces, runtime data collection systems, and extended programmability. These enhancements will increase reliability and allow for more precise control and expanded material flexibility. A second phase of upgrades featured design changes to key machine components to increase material usage efficiency, making this asset one of the most technologically advanced spooling lines in the world. Web also made improvements to two other spooling assets at Web Fort Wayne this year, adding a new slitting system to one line and making mechanical modifications to another line to increase efficiency and quality.

Web continues to focus on adding capacity to meet the growing demand for spooled materials. These investments come less than year after the company acquired a high-speed, wide-width, large OD slitting asset. This line allows for larger 60" output rolls that support longer manufacturing runtimes with fewer changeovers.

“We continue to grow our Large Formatting platform,” says Jason Surman, director of sales, Consumer Products. “The industry-leading spooling, slitting, and printing capabilities located at Web Fort Wayne are positioning our company to be the formatter of choice to the health and hygiene markets.”

www.webindustries.com

Athea Laboratories

Athea Laboratories has been in business for over 50 years and is the leader in specialty wipes, liquid, and powder contract manufacturing and packaging. Its expertise and experience gives customers an extensive variety of product formats to serve numerous end-user markets with their private labeled product. As an EPA and FDA facility, Athea’s manufacturing capabilities include custom wipe converting, custom formula development, blending services, onsite chemists, formula-substrate compatibility testing, graphics and technical and regulatory support. Athea can offer its customers a turnkey solution to their packaging needs at low minimums.

www.athea.com

Aurora Specialty Textiles Group

For over 130 years, Aurora Specialty Textiles Group, Inc. (Aurora) has been a leading, world-class finisher of both woven and nonwoven fabrics. Utilizing state-of-the-art equipment and technologies, Aurora specializes in coating and finishing products for print media, home furnishings, and industrial belting, pressure sensitive tapes and medical and industrial products.

Recently, Aurora has opened a new state-of-the-art manufacturing operation in Yorkville, IL, which offers ultra wide width (134-inch) coating and finishing techniques. This enhanced capability secures its place in today’s changing global textile market as an innovative global provider of textile solutions. This move expands Aurora’s ability to provide product solutions for a wide range of applications and further strengthened its ability to be responsive, efficient and price competitive.

Aurora is a Meridian Industries Inc. company, which is a privately held, family-owned company headquartered in Milwaukee, WI.

www.auroratextile.com

Beckmann Converting

Beckmann Converting continues to upgrade its high tech, ultrasonic laminating equipment, both in bonding capability and in web handling, to create wide web, multilayer and multifunction composites. Upgrades have allowed the company to process more efficiently and to process more types of raw materials. Beckmann operates as a contract or toll laminator and is able to create, from two-layer composites to six-layer composites. It can create them as wide as 120 inches and slit in line, to any width a customer or its next step converter requires. These composites can be combinations of nonwovens, films, knits, wovens or meshes.

Ultrasonic laminating has a unique place in the creation of multi-layer composites because nothing other than the original materials are used in that process. This makes it a true “green” process. As long as there is sufficient thermoplastic content in the layers to be laminated, the ultrasonic energy melts the materials at the bonding points, making it the bonding link of the individual layers, unlike adhesive bonding, which introduces foreign substances into the composites. Because ultrasonic lamination is a “point bonding process,” all of the properties of the raw material layers, in between the bond points, are the same as before lamination, which include properties such as strength, loft, breathability, filtration and chemical resistance. Beckmann has successfully produced multi-layer composites for applications such as filtration, environmental, protective apparel, protective covers, healthcare products, cleanroom wipes and many more.

www.beckmannconverting.com

Elsner Engineering

Elsner Engineering has been producing converting machinery for various paper, film, foil and nonwovens end-uses for decades. Its experience coupled with its passion to bring innovative, purpose-built machinery to life means Elsner is a great resource when it comes to strategizing on best ways to boost productivity, especially as related to integrating automation into a business’s production lines. Elsner’s consultative approach can help businesses determine the value of automation based on their unique manufacturing circumstances. Elsner’s goal is to help its customers get on-track to Turn the Key and GO.

www.elsnereng.com

Kleen Test Products Corporation

Kleen Test Products is a privately held, family-owned company headquartered in Port Washington, WI, that’s been in business for over 70 years. Kleen Test’s product and service offerings include contract manufacturing and product development services in a number of product segments such as wet wipe and dryer sheet manufacturing, die cutting nonwovens, coating and conversion of specialized nonwoven products, liquid filling and bulk blending.

Recently, Kleen Test Products launched SNAP PAD, a patented, all-in-one single-use applicator that allows the user to saturate the nonwoven at the time of use. By gently squeezing the outer casing of the applicator, a burst of solution is released onto the nonwoven pad. The volume of solution and the diameter of the pad applicator can be customized to meet a product’s specifications. SNAP PAD can be used for a number of applications including first aid, beauty care, personal care, home care, automotive and more.

www.kleentest.com

Majilite Corporation

Majilite Corporation, a Meridian’s Industries Company, located in Dracut, MA, is a custom manufacturer of films and film laminates. Most any liquid polymer, solvent or water based, can be used to produce films in the 0.5 to 10.0 dry mil range. Majilite can then laminate these films, to most any fabric, woven or nonwoven, or further process them to create single or multi-layer composites. The company has the following coating capabilities: cast or transfer films, direct coating, reverse roll coating, saturation, printing, and knife over roll coating. Majilite also has the capability to post laminate, emboss, buff or sand, quilt, and rotogravure printing. Its plant is state-of-the-art not only in its capabilities but also in how it can virtually eliminate solvent emissions from its processes. R&D and product development labs are located at Majilite’s plant site along with a Quality Control laboratory.

www.majilite.com

Micrex

Micrex Corporation is the developer and manufacturer of the Micrex/Microcreper family of compressive treatment machinery for nonwovens, paper, films, composites, and textiles. Companies worldwide use Micrex technology to add softness, bulk, drape, absorbency, extensibility, and stretch to a wide range of products.

Micrex expands upon its capabilities by providing product development through the Micrex Innovation Lab. This integrates with contract Microcreping services for those firms whose current needs do not yet require the purchase of a dedicated Micrex/Microcreper system. Micrex is prepared to support projects from initial development through large scale production. All nine configurations of Micrex/Microcreper are available for contract production.

In 2016 no-cost lab scale screening trials are available to qualified customers. For information about this program, visit: http://micrex.com/screening-trials/.

www.micrex.com

National Wiper Alliance

National Wiper Alliance (NWA) is the largest operation in the U.S. focused on nonwoven dry wipes converting and private labeling. Operating out of its 500,000 square foot state-of-the-art facility located just outside Asheville, NC, NWA has over 30 converting lines offering slitting, inner folding, folding, sheeting, and perforating—both with core and coreless, as well as printing—with both inline and dedicated print lines. Additional in-house services offered include product development, sample runs, product testing, warehousing, customer inventory management, distribution and logistical support. Products converted by NWA can be found in the retail, aerospace, automotive, industrial, food service, hospitality, medical, government, military and janitorial markets.

Earlier this year, NWA purchased a 42-acre site with a 152,000 square foot warehouse located near its current facility. Jeff Slosman, president of NWA, says, “With the growth we have experienced over the past few years, ensuring we would have enough space to maintain our efficiencies was a concern. The new location will guarantee we have space to continue to offer our customers the service they have come to expect when working with NWA while offering us the land for expansion in order to handle our continued growth for the years to come.”

Proudly registered to ISO 9001:2008 standards, National Wiper Alliance and its owner Jeff Slosman have received numerous awards over the past year. These awards include: SBA-North Carolina 2015 Small Business Person of the Year – Jeff Slosman; NC Chamber of Commerce – 2015 Manufacturer of the Year – Honorable Mention; Business NC Magazine – 2015 NC Small Business of the Year and Wake Forest Family Business Center – 2016 NC Family Business of the Year.

www.nationalwiper.com

Nonwovens of America

Nonwovens of America, Inc. (NOA) is located in Swannanoa, NC, operating a 5.4-meter air-lay needlepunch line and running colors in a weight range of 3.5 ounces per square yard to 34 ounces per square yard. In addition to the needlepunch line, NOA provides custom converting services which include a 10-color, 99” wide rotary screen print line, blanket lines, an inline calendar, and slitting and re-rolling. NOA offers toll converting services on the needlepunch line as well as all other converting services. The main areas of focus are automotive, retail, geotextile, industrial and emergency blankets. NOA provides in-house customer service, product development, warehousing, logistics and distribution support.

www.nonwovensofamerica.com

Rockline Industries

Rockline Industries is a family-owned and run business since its founding in 1976. The company has grown from a 35-person company to a 2000-person organization designing, making and shipping products all over the world. Rockline is committed to safety, quality, integrity, sustainability, and excellence in everything it does. Rockline Contract Manufacturing Services (CMS) are built on the core values of integrity, dignity, respect, and hard work.

The expertise Rockline CMS continues to demonstrate, guides customers into new product solutions and leads continuous improvement in innovations with materials, manufacturing platforms and technologies. CMS offers a fully diversified portfolio of converting and packaging equipment in an environment that is designed to be a world class leader in quality, while intentionally practicing strategies that minimize its global footprint.

Values: Rockline says its values define them. They reinforce to all of their stakeholders—customers, associates, suppliers and communities—just how much Rockline appreciates them. They allow Rockline to build a value-based business and reputation within the industry at large. Within the contract manufacturing sector, its values ensure that Rockline maintains a global recognition as the premier supplier in the industry, producing innovative solutions, ensuring mutually profitable partnerships and providing customers with important and trusted services that create lasting relationships.

The word “urgency” describes the sense with which Rockline seeks to earn recognition by its customers as the unmatched leader in contract manufacturing. This urgency involves five basic imperatives — Renew (invest all earnings in continuous improvement), Respect (treat others as we want to be treated); Integrity (do the right thing); Teamwork (individual goals are secondary to team goals); and Excellence (best in class). Rockline fosters a culture of integrity, service and personal growth. The company delivers excellence in its products, process and services.

Integrity: Rockline does not compromise integrity for financial gain. Its partnerships are managed with the utmost respect while striving for manufacturing flexibility and to provide the best net value to our customers.

Every Rockline associate is asked, “Do what you think is right – every day.” These simple words can make for tough choices, but Rockline says it will never stop trying to do the right thing. For example, the company has a reputation in the wipes industry of uncompromising integrity with respect to maintaining strict confidentiality to protect and preserve intellectual property for the ongoing business security of its customers.

Continuous Improvement: Rockline embraces continuous improvement through product innovation, capital reinvestment and through dedicated passionate leadership and cross functional teams. Its values are applied to all stakeholder relationships—from customers, associates, and suppliers on out to the communities at large whose needs it meets with uncompromising effort. It works every day to confirm just how much Rockline values each and every one of them. Rockline understands this is the only way to build and sustain the reputation it seeks within the industry. In the words of its CEO Randy Rudolph, “We won’t make a product we wouldn’t buy for ourselves. We aim for the sweet spot. Rockline is big enough to give our customers the resources and vision of a global company, yet we are small enough to value each and every customer.”

Innovation: At Rockline, its core strength is the quality and innovation of its product. The focus of its contract manufacturing group is to deliver excellence in customer service by supporting its customers with custom manufacturing and cutting-edge product and packaging while strengthening its speed to market. This is supported by a winning combination of technical leadership along with the most diverse manufacturing platforms in the industry. It listens, innovates and collaborates with its customers to deliver customer specific solutions that leverage its expertise in material, manufacturing and innovation.

Sustainability: It is Rockline’s commitment and passion to put its own reputation on the line every day, to measure and report its own progress so customers don’t have to. That’s what sustainability means to them. For information about Rockline’s environmental program success of the past six years and its 2020 environmental targets download the Sustainability Report: http://www.rocklineind.com/environmental-sustainability/. Among the key accomplishments highlighted in the report is a 21% intensity reduction in energy compared to 2009 levels. Over the last six years, the company has focused on energy efficiency and invested in lighting upgrades, motion sensor installations, roof insulation projects, smart compression systems, the adoption of battery-electric forklifts, and the installation of a geothermal heating and cooling system. Energy reduction also provides the benefit of reducing the company’s carbon footprint and helped the company to achieve a 22% intensity reduction in greenhouse gas emissions.

Rockline continues to aggressively move from fossil fuels toward clean, low carbon energy, designing waste and inefficiency out of its system, and embracing strategies like reuse, recycling, and energy recapture to reduce landfill use and waste water production. Rockline strives for Ecological Intelligence in its end products, using less material where it can, and sourcing natural and recycled materials wherever possible.

www.rocklineind.com

Superior Felt & Filtration

Superior Felt & Filtration is a quality and customer service driven manufacturer, distributor and converter of nonwoven felt and filtration media. Superior offers a wide range of nonwoven products to meet the immediate needs of multiple technical markets. Superior serves numerous markets including medical, automotive, aerospace, appliance, industrial, decorative and more. Already stocking the largest inventory of micron, CFM, synthetic, high temperature, FDA grade and SAE wool felts in North America; Superior is also the North American distributor and converter of Technostat, a sub-micron, high-efficiency filter media: The versatility of Technostat allows Superior to exceed expectations in Viral/Bacterial, CPAP, NIOSH, Respirator, HEPA and breathable packaging and wound care markets. SFF also provides white room fabrication which further supports its position in lamination, ultrasonics, slitting, heat sealing, die-cutting, printing, private label packaging and other value added services. From container loads of roll good media to life saving medical filtration technology, Superior can take an idea from concept to completion.

www.superiorfelt.com

Web Industries

Web Industries continues to focus on improving capabilities and increasing capacity to better serve the health and hygiene markets. In 2016, the company made significant investments to upgrade several spooling assets at the company’s Fort Wayne, IN, facility. Home to several of the largest custom-designed spooling lines in the work, Web Fort Wayne processes nonwovens, films, and other materials, and provides contract converting, spooling, printing, and supply chain management services in a single location.

Capable of accepting 120" wide master rolls, Web has invested in upgrading its “large format spooler” to utilize the latest industrial control interfaces, runtime data collection systems, and extended programmability. These enhancements will increase reliability and allow for more precise control and expanded material flexibility. A second phase of upgrades featured design changes to key machine components to increase material usage efficiency, making this asset one of the most technologically advanced spooling lines in the world. Web also made improvements to two other spooling assets at Web Fort Wayne this year, adding a new slitting system to one line and making mechanical modifications to another line to increase efficiency and quality.

Web continues to focus on adding capacity to meet the growing demand for spooled materials. These investments come less than year after the company acquired a high-speed, wide-width, large OD slitting asset. This line allows for larger 60" output rolls that support longer manufacturing runtimes with fewer changeovers.

“We continue to grow our Large Formatting platform,” says Jason Surman, director of sales, Consumer Products. “The industry-leading spooling, slitting, and printing capabilities located at Web Fort Wayne are positioning our company to be the formatter of choice to the health and hygiene markets.”

www.webindustries.com